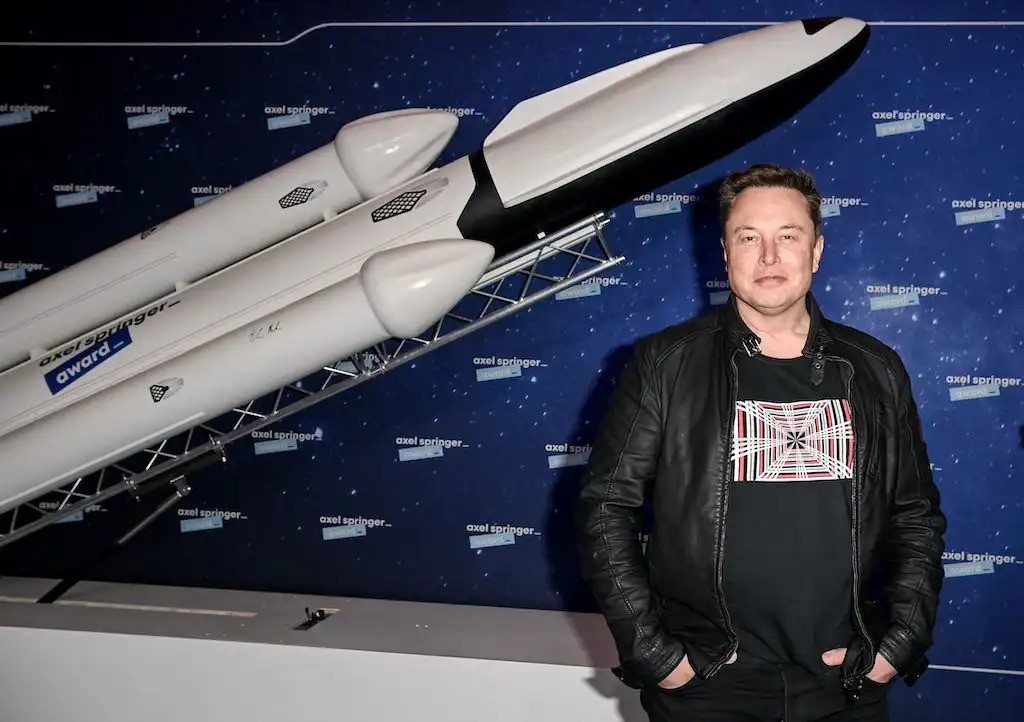

In 2001, Elon Musk flew to Russia to buy rockets to start SpaceX. They wanted $8 million per rocket... More than he wanted to spend. But on the flight back, he had an epiphany. Here's the decision that would transform space travel forever:

Before SpaceX, launching anything into space was insanely expensive. The Space Shuttle cost $1.5 billion per launch. That's $54,500 per kilogram to reach orbit. Only governments and mega-corporations could afford space. But everything was about to change...

Content Warning: Adult Content

Click to Show

In 2001, Elon Musk had a crazy idea: Send a small greenhouse to Mars to inspire people about space exploration. But when he looked into launch costs, he was shocked. What he discovered would reshape the entire space industry:

Content Warning: Adult Content

Click to Show

Musk flew to Russia to buy refurbished ballistic missiles. The Russians quoted $8 million per rocket and saw him as an inexperienced upstart. On the flight back from Moscow, Musk had an epiphany that would disrupt the entire industry: He could build the rockets himself.

Content Warning: Adult Content

Click to Show

With $100 million from selling PayPal to eBay, Musk founded SpaceX in 2002. His approach was revolutionary: Manufacturing about 70% of components in-house, unlike traditional aerospace companies. But the early years tested everything they had...

Content Warning: Adult Content

Click to Show

The first three Falcon 1 launches failed between 2006 and 2008. SpaceX was nearly bankrupt. Musk had to borrow money just to make payroll. Then came the breakthrough that changed everything:

The fourth launch succeeded on September 28, 2008. NASA awarded SpaceX a $1.6 billion Commercial Resupply Services contract. But Musk wasn't satisfied with just reaching orbit. His vision would transform space travel forever:

Make rockets reusable. Traditional rockets were single-use, like throwing away an airplane after one flight. SpaceX aimed to land rockets vertically and reuse them. Everyone said it was impossible. Here's what made the difference:

After multiple explosive failures, SpaceX achieved the impossible: The first successful landing of a Falcon 9 first stage on December 21, 2015. This wasn't just a technical achievement. The impact on costs was revolutionary:

Content Warning: Adult Content

Click to Show

Reusing the first stage saves $46.5 million per launch. The Falcon 9 now delivers payloads to orbit for $2,720 per kilogram. That's a 95% reduction from Space Shuttle costs. But Musk's ultimate goal reaches even further:

Get to Mars. Not just visit—colonize it. Making space travel 1000x cheaper became the mission. SpaceX's solution is extraordinary:

Content Warning: Adult Content

Click to Show

Enter Starship: • Fully reusable (both stages) • Rapid turnaround (hours between launches) • Uses methane fuel (can be produced on Mars) • Mass-produced like cars The goal is an insane $10 per kilogram to orbit.

SpaceX's lean approach is the key: • Build fast, test fast, fail fast • Vertical integration for speed and cost • Flat organization to cut bureaucracy • Continuous iteration and improvement The deeper lesson transforms everything:

The impossible becomes possible when you: 1. Focus maniacally on cost reduction 2. Build in-house to control quality 3. Move fast and learn from failures 4. Think in orders of magnitude This mindset revolutionizes industries.

The real lesson from SpaceX? It's not just about rockets. It's about doing more with less: • 70% in-house manufacturing • Rapid iteration over perfection • Lean teams, massive output This principle mirrors my own business journey:

I built two multimillion-dollar companies with minimal resources. My first business started in high school. It grew big and we sold it for $60M. My second? Built to $10M+ revenue with just 5 employees in 3 years. The secret lies in efficiency:

Focus on efficiency over effort. Like SpaceX, we: • Built in-house capabilities • Moved fast and learned faster • Stayed lean and nimble Most importantly, we maximized output while minimizing input.

This approach works in any industry: Whether you're building rockets or running a startup, success comes from maximizing output while minimizing input. Want to learn how to do more with less?

Follow me @nealtaparia for insights on: • Building lean businesses • Working efficiently • Creating lasting wealth I share everything I've learned about working smart, not hard.